Circular Satin Finish: The Art of Enhancing Watchmaking and Mechanical Surfaces

Circular satin finish, also known as circular graining, is an essential decorative technique in the watch industry and is showcased on pinions, wheels, dials, and oscillating weights. Some bridges also use it to enhance their appearance. Let’s explore what this technique entails, its benefits, and how it is implemented in high-precision production.

What is Circular Satin Finish?

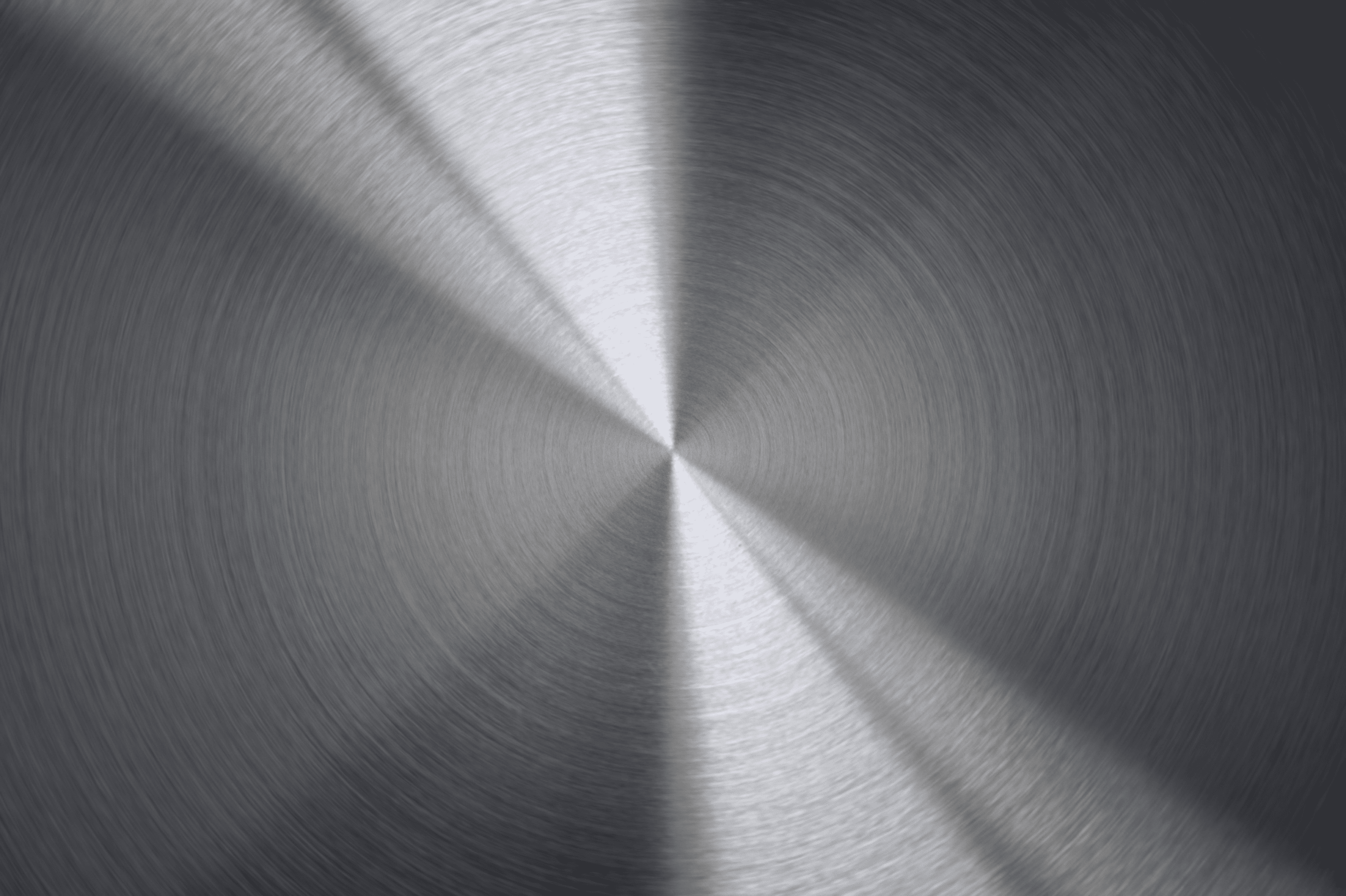

Circular satin finish consists of creating fine, uniform lines on the surface of a part by rotating it against an abrasive. This abrasive is typically emery paper, most often attached to a hardened-ground stainless steel ruler or to wood (a cabron). This process produces concentric circles that reflect light uniformly, offering a refined visual effect and a silky touch.

In watchmaking, this type of finish highlights the meticulous craftsmanship involved.

The Advantages of Circular Satin Finish

- High-End Aesthetics: Circular satin finish imparts a subtle texture that captures light, creating elegant and dynamic reflections.

- Concealing Imperfections: This technique helps mask micro-scratches and surface irregularities, resulting in a more uniform appearance.

- Infinite Customization: It is possible to vary the width, depth, and intensity of the lines to achieve tailor-made effects according to the client’s preferences.

The Technical Challenges of Circular Satin Finish

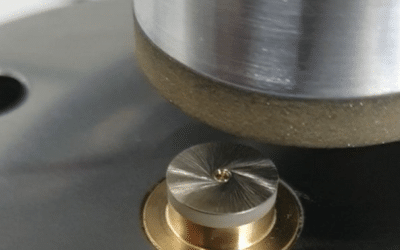

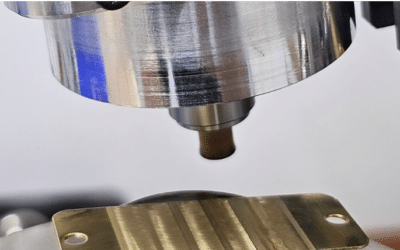

Achieving a perfect circular satin finish is not without its challenges. The stability of the part, the clamping (which can be complicated if done before gear cutting), the precision of the tools, and consistent pressure are crucial factors for obtaining perfect repeatability. There are also different satin finishing applications, such as external (easier access) and internal (more difficult to access). The SwissKH machine offers both possibilities.

SwissKH offers two machines:

- Manual: For very high-end, piece-by-piece work. See our Circular graining (cerclage) on the product page.

- CNC: A CNC machine that enables both straight and circular satin finishing, improved consumable management, and ultimate precision for a controlled and refined finish.

Circular Satin Finish for Premium Brands

Whether in luxury watchmaking, jewelry, or micromechanics, circular satin finish remains a hallmark of quality. It conveys the engineering precision and attention to detail that define the finest manufacturers.

The future of this technique lies in innovation: ever more efficient machines, new materials, and optimized processes to reduce production times while enhancing quality.

At SwissKH, we are passionate about these challenges and are committed to supporting our clients in their pursuit of perfection.

🔧 Would you like to learn more about circular satin finish and discover our tailored solutions? Contact us!